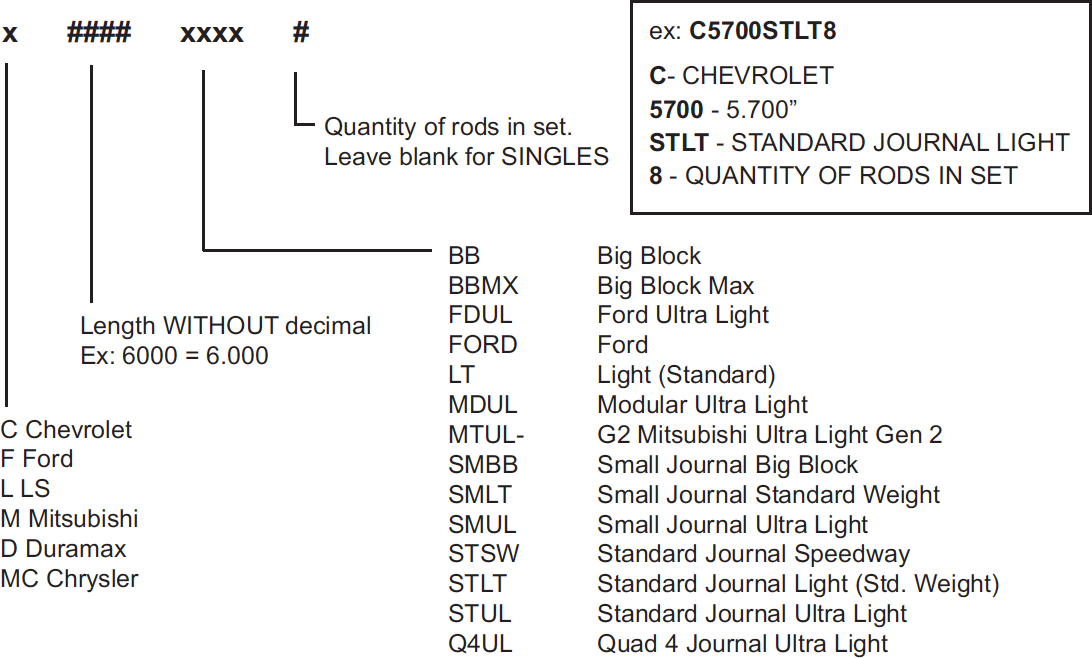

Select Your Application

OLIVER Rods Are Better By Design™

All Oliver rods are precision-machined using only premium mill-certified aircraft quality E4340 AQ chromoly alloy, heat-treated to produce a 100% martensite grain structure.

2X DOUBLE Heat Treat

Full Stress Relief After Rough Machining Quench and Tempered for 100% martensitic grain structure for optimized durability and strength

4340 AQ Material

Higher grade more expensive than standard meeting AMS2301 vacuum furnace degassed for higher cleanliness and improved strength

Narrow Bore Spacing

Tightest bore spacing in the industry increasing clamp load at the big end bore split joint and maintaining bore/bushing roundness

In Process Air Gauging

Most accurate bore measurement possible Parallelism and concentricity implemented prior to the hone operation opens up the potential for extremely consistent bores for the gauging of the part. With only .002 travel and a measurement tolerance of .00002, our gauges offer the ability to control the part and therefore, give us authority over the entire gauging process.

Parabolic Beam Design

Oliver I-beam connecting rods feature our exclusive “Parabolic Beam®” design that reduces beam stress and delivers the highest strength-to-weight ratio of any